The Superior Design of Our Kingpinless Casters

Casters make moving heavy loads far easier in a commercial or industrial environment, but not all casters are created equally. Traditional kingpin casters are prone to failure, especially when towed because they focus all the forces of linear travel and rotation through a relatively small area, the kingpin.

At RWM Casters, we offer a stronger, longer-lasting alternative — the Kingpinless™ caster. We are the inventors of the Kingpinless™caster, a design that joins the caster plate to the rest of the caster rig through a single set of high-strength ball bearings that ride in a case-hardened raceway. By eliminating the kingpin, the forces are distributed more evenly throughout the caster rig. Our casters feature industry-leading designs, quality, and versatility, and we are proud to manufacture the vast majority of our products right here in the United States.

Features & Benefits of Kingpinless™ Casters

The Kingpinless™ caster has become the industry standard for heavy-duty applications and towing because its superior design lasts longer and puts up with more wear during everyday operation. Some of the key benefits and features of choosing a Kingpinless™ caster design include:

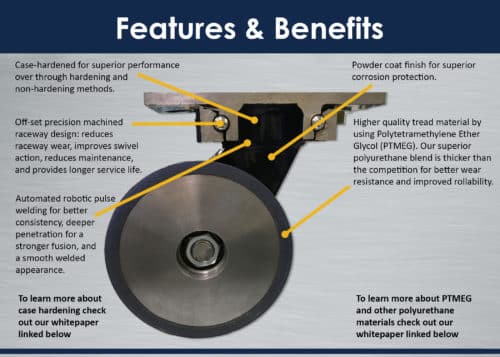

- High-strength ball bearings: Durable, long-lasting bearings provide smooth rotation of the casters, making moving even the heaviest loads easy.

- Case-hardened raceways: Case hardening provides a hardened surface that resists wear from the bearings while preserving the underlying steel’s flexibility to absorb shock loads without cracking the raceway.

- Offset raceway design: Distributes load more evenly to reduce wear and extend the service life of the bearing.

- Durable neoprene seals: Long-tasting, flexible seals keep out dirt and moisture that can lead to wear, corrosion, and premature failure.

- Automated pulse welding: Robotic welding ensures consistent, high-strength welds every time without defects that could cause cracked welds or caster failure.

- Available PTMEG wheels: Our PTMEG polyurethane wheels are thicker, roll easier, and last longer than competing polyurethane designs. We also offer metal, rubber, nylon, plastic, and phenolic wheels.

- Available zinc or powder coat finishes: Our zinc or powder coat finishes offer significantly better corrosion and abrasion resistance than typical painted finishes.

Kingpinless™ Applications

Our Kingpinless™ casters offer long-lasting performance and durability for almost any commercial or industrial application, including:

- Aerospace

- Automotive

- Bakery

- General manufacturing

- Medical

- Scaffolding

- Textile

- Tire manufacturing

- Towing/tow lines

- Track wheels

Find a Kingpinless™ Caster Distributor Near You

When you need a heavy-duty caster that you can count on for reliable, trouble-free operation no matter the size of the load, choose a Kingpinless™ caster from RWM Casters. Our company has provided innovative material handling solutions since 1935, and and we offer a full range of kingpin, kingpinless, and custom casters to fit nearly any application. Our patented Kingpinless™ design has never been improved upon, and each caster we offer provides unmatched performance, durability, and longevity. We feature distributors throughout the United States for quick access to top-quality casters no matter your location, and we offer industry-leading service and support with competitive pricing and short lead times.

Call 800-634-7704 today to request a quote for Kingpinless™ casters or to find your nearest distributor!

Case Hardening White Paper: https://www.rwmcasters.com/wp-content/uploads/2022/03/Case-Hardening-Final.pdf

PTMEG Polyurethane White Paper: https://www.rwmcasters.com/wp-content/uploads/2023/03/Polyurethane_Material.pdf